SPS Shop - Flender

More than ten years of international marketing experience and a range of over one million products speak for themselves – SPSshop is your specialist dealer when it comes to high-quality electronic components in the industrial sector.

Flender stands for comprehensive knowledge in all questions of mechanical drive technology, as well as the utmost quality in all products and services. Highly qualified and dedicated employees have always been the key to our innovative strength and productive capacity. But they are also the basis of our special consulting expertise, which is supported by a virtually unlimited portfolio.

WE OFFER YOU

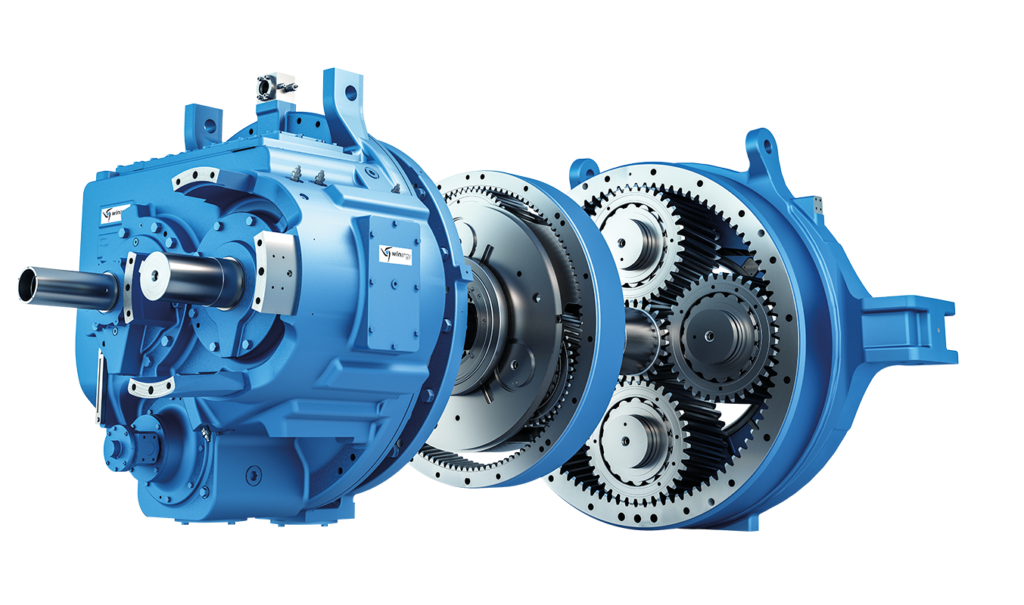

GEAR UNITS

We offer you helical and planetary gear units out of our standard modular construction system or as a finished application solution.

COUPLINGS

The worldwide largest portfolio of industry couplings offers flexible, highly flexible, torsionally rigid, hydrodynamic as well as backlash-free solutions and railway couplings.

FURTHER COMPONENTS

Our modular construction system comprises all parts of the gear unit periphery from motor bell housings and torque reaction arms over swing-bases and oil-supply systems to complete bevel gear sets.

N-EUPEX - A CLASSIC COUPLING FOR THE FUTURE

- Damping shaft coupling that can be used universally to compensate for shaft misalignment

- Nominal torque range from TKN = 12 Nm up to 85,000 Nm with 23 sizes

- Temperature range from –50 °C to +100 °C

New in 2022: The types ERN, B, DKS and TPU elastomers – download the Techreport now

Find out more about the three couplings N-EUPEX ERN with torque limiter for more safety in your drivetrain, N-EUPEX B plus clamping element for increased serviceability and the shortest double-cardanic N-EUPEX DKS on the market.

High-quality solutions for your plant

A wide variety of N-EUPEX® types offer optimum coupling solutions for every challenge. Couplings with a double-cardanic design, with torque limiter, with clamping element or short design enrich the extensive modular system of pin couplings. The flexible modular system provides sustainable options that optimize machines and systems and reduce maintenance. A high combination diversity and flexibility is ensured by diverse components.

Robust and proven a million times

Due to their torsional flexibility, N-EUPEX® couplings can move critical torsional vibrations away from the operating area of mechanical equipment in such a way that no negative effects on the drive train are to be expected. N-EUPEX couplings are made of high-quality cast iron. The flexible elements made of synthetic rubber (NBR) are available in different degrees of hardness for many applications. In addition, elastomers made of thermoplastic polyurethane (TPU) and of NBR with fabric inserts for increased load-bearing capacity are offered. Metal pins and flexible elements are designed so that no wear occurs when they are properly fitted.

Your benefits at a glance

- Fail-safe for maximum operational reliability

- Three-part type suitable for plug-in assembly and simplified replacement of elements

- Choice of elastomer hardness to suit various applications

- Suitable for use in potentially explosive environments; certified according to

2014/34/EU (ATEX) - High degree of availability of parts ex stock

Established as an industrial standard, worldwide in use

- Mining and Cement: heating technology

- Oil and Gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Plastic and Rubber: single- and double-screw extruders

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators

- Food and Beverage: lauter tuns, reactors, agitators, mixers

Did you know?

Original FLENDER® elastomers ensure the optimal operation of your system. The flexible elements of the N-EUPEX coupling are subject to compression. If the flexible elements are irreparably damaged, the hub parts come into contact with metal. This “emergency operation capability” is required, e.g., in the case of fire pump drives.

N-ARPEX All-Steel Coupling

THE BEST-PERFORMING COUPLING ON THE MARKET

- Backlash-free, torsionally rigid all-steel multi-disk coupling

- Nominal torque range from TKN = 350 Nm to 2,000,000 Nm

- Temperature range: from –50 °C to +280 °C

Investment costs, lifecycle costs, power-to-weight ratio, fitness for use and the cost of purchasing couplings are key considerations for equipment manufacturers.

With the introduction of the new N-ARPEX® all-steel multi-disk coupling Flender is continuing the success story of the proven ARPEX® series of couplings. The N-ARPEX is currently the most powerful coupling on the market due to the consistent further development of the ARPEX – a leap in performance that in this size could only be achieved by means of various design features. With the N-ARPEX, Flender delivers the optimum price-performance ratio.

With our all-steel couplings, the reliable transmission of torque between the shafts to be connected is backlash-free, torsionally rigid and flexurally elastic. This enables them to compensate for axial, angular and radial misalignment. Our multi-disk couplings are not prone to wear and are maintenance-free.

The couplings have been designed for use in potentially explosive environments as defined in Directive 2014/34/EU (ATEX) and comply with the requirements in standards

API 610 and API 671.

Your benefits at a glance

Lower costs through higher performance

An optimized plate pack design and a revised component design enable transmission of very high torques and speeds.

Low bearing loads through low weight

A marked increase in bore capacities with standard hubs increases performance capability and lowers the N-ARPEX’s weight.

Versatility for maximum fitness for use

Its suitability for use at low temperatures between –50 °C and +280 °C and its high misalignment capacities of up to 1° enable the N-ARPEX to be used for many different purposes in special conditions.

Easy selection and reduction in storage costs

The bundling of the ARPEX ARS®, ARC® and ARP® series together to make a single serie N-ARPEX ARN® results in a reduction in complexity from 67 to 37 couplings. Thus, storage costs are reduced. Choosing the desired coupling is much easier.

Made in Germany, worldwide in use

- Petrochemistry: pumps, fans, compressors, air condensers, jack-up rigs, driers, mixers, cooling towers, agitators, reactors, installation vessels

- Power Generation: air condensers, generators, gas turbines, cooling towers, water turbines, boiler feed pumps

- Pulp and Paper: waste paper, wet section, dry section, smoothers and cylinders, reel winders, coating machines, calenders, wastewater purification plants

- Water and Wastewater: pumps, aerators, water screw pumps

- Cranes: hoisting and luffing gear systems, slewing gear systems, trolley and travel gear systems

- Marine and Shipbuilding: single-engine ships, multi-engine ships, dredgers, generator gearboxes, installation vessels

Did you know?

We make the N-ARPEX your N-ARPEX. Beyond the broad standard program, we give you the opportunity to customize the coupling according to your specific needs. Thus, in addition to various hub and flange types, we can offer you special designs such as one which prevents leak currents between coupled devices. Our coupling experts are happy to advise you.

N-EUPEX - A CLASSIC COUPLING FOR THE FUTURE

- Damping shaft coupling that can be used universally to compensate for shaft misalignment

- Nominal torque range from TKN = 12 Nm up to 85,000 Nm with 23 sizes

- Temperature range from –50 °C to +100 °C

New in 2022: The types ERN, B, DKS and TPU elastomers – download the Techreport now

Find out more about the three couplings N-EUPEX ERN with torque limiter for more safety in your drivetrain, N-EUPEX B plus clamping element for increased serviceability and the shortest double-cardanic N-EUPEX DKS on the market.

High-quality solutions for your plant

A wide variety of N-EUPEX® types offer optimum coupling solutions for every challenge. Couplings with a double-cardanic design, with torque limiter, with clamping element or short design enrich the extensive modular system of pin couplings. The flexible modular system provides sustainable options that optimize machines and systems and reduce maintenance. A high combination diversity and flexibility is ensured by diverse components.

Robust and proven a million times

Due to their torsional flexibility, N-EUPEX® couplings can move critical torsional vibrations away from the operating area of mechanical equipment in such a way that no negative effects on the drive train are to be expected. N-EUPEX couplings are made of high-quality cast iron. The flexible elements made of synthetic rubber (NBR) are available in different degrees of hardness for many applications. In addition, elastomers made of thermoplastic polyurethane (TPU) and of NBR with fabric inserts for increased load-bearing capacity are offered. Metal pins and flexible elements are designed so that no wear occurs when they are properly fitted.

Your benefits at a glance

- Fail-safe for maximum operational reliability

- Three-part type suitable for plug-in assembly and simplified replacement of elements

- Choice of elastomer hardness to suit various applications

- Suitable for use in potentially explosive environments; certified according to

2014/34/EU (ATEX) - High degree of availability of parts ex stock

Established as an industrial standard, worldwide in use

- Mining and Cement: heating technology

- Oil and Gas: pumps, fans, compressors, air condensers

- Power Generation: pumps, fans, compressors, air condensers, water turbines

- Chemicals and Pharmaceuticals: driers, lauter tuns, pumps, fans, compressors, mixers, agitators, reactors

- Plastic and Rubber: single- and double-screw extruders

- Pulp and Paper: wastewater purification plants

- Water and Wastewater: aerators

- Food and Beverage: lauter tuns, reactors, agitators, mixers

Did you know?

Original FLENDER® elastomers ensure the optimal operation of your system. The flexible elements of the N-EUPEX coupling are subject to compression. If the flexible elements are irreparably damaged, the hub parts come into contact with metal. This “emergency operation capability” is required, e.g., in the case of fire pump drives.

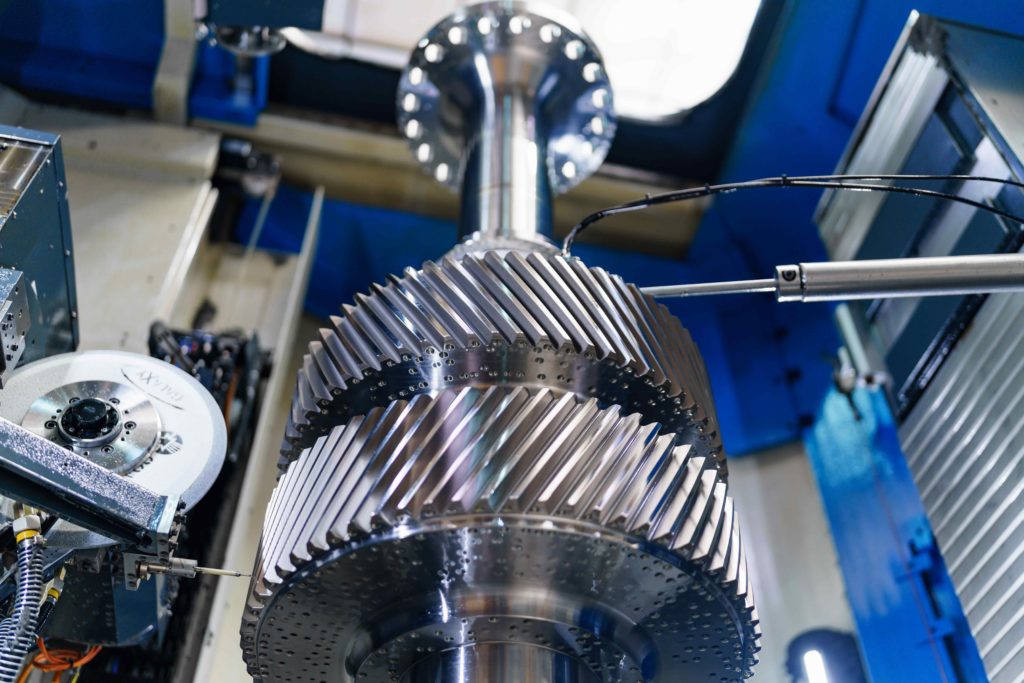

Turbo gearboxes from Illkirch-Graffenstaden

We have so far manufactured and installed more than 15,000 gearboxes worldwide. Every one of them is tailor-made to meet customer requirements.

Unique and reliable: the Flender works in Illkirch-Graffenstaden develops and produces high-precision turbo gearboxes. Our gearboxes are capable of transmitting the power of an ocean liner with the precision of clockwork. We produce tooth modules that fulfill our customers’ specific requirements. This challenge we are able to meet every day thanks to the knowhow, the care and the precision of our employees that are involved in every phase of development and production.

DESIGN

Daily development of new products

Every one of our gearboxes is an individual piece. Innovations and planning of parts to meet the customer’s individual requirements in an industrial, standardized and automated process are the challenge our engineering design department is able to meet every day.

Our engineers analyse and plan high-performance products in accordance with the customer’s specifications. They work on them with an agility and reactivity that is aimed at ensuring continuous improvement of the process.

THE QUALITY SERVICE

Best quality worldwide

One of the main reasons for the outstanding quality of our turbo gearboxes is our quality management. Every one of our employees works daily to supply our customers with machines of the highest quality. Our quality assurance system is integrated into all our processes, from sales and marketing through to delivery, to enable us to ensure the the conformity of each product. And because we strive to do better every day, since 2001 we have been working to continuously improve the entire process by using lean tools. Whether it is in our offices or in production, continuous improvement is part of our DNA.

High-performance gearboxes (turbo gearboxes) for step-up and step-down transmission

Contact Us

SPSshop GmbH & Co. KG

Starkstr. 7

D-85098 Grossmehring / Germany

Phone: +49 (0) 8407 / 30 40 1 – 00

Telefax: +49 (0) 8407 / 30 40 1 – 10

E-Mail: info@spsshop.eu